Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Industry News >

One Thailand clients needs one set of Capacity 5 Tons Per Hour Sand Dryer for their small dry mortar production line, and their basic information is as follows: their raw material is river sand, after washing, the moisture content is about 15%, need to use the sand dryer to reduce its moisture content to be less than 1%, and they prefer to use coal as fuel, the dried sand needed is 5 tons per hour.

River Sand after being washed

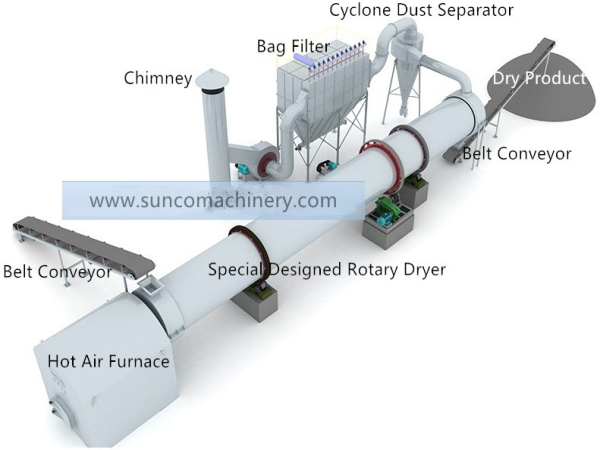

According to their requirements, Sunco Machinery designed one set of output capacity 5 t/h sand drying plant accordingly.

Sand Drying Plant Layout drawing

◆ Coal fired Hot Air Furnace to burn the natural gas or diesel to generate high temperature air for the sand drying process.

◆ Input Belt Conveyor sends the wet sand into the sand drier.

◆ Silica Sand Dryer supply the drying chamber and water evaporation space, and reduce the moisture content of the wet sand as need.

◆ High Pressure Draft fan working with the air duct make the high temperature air goes into the sand drying machine, and sucks out the exhaust air mixed with water vapor out of the dryer in time.

◆ Cyclone Dust Separator separates the fine dust from the exhaust air, and after that the exhaust air goes into atmosphere through Chimney, the dust falls out of the cyclone dust separator and to be collected by bag filter.

◆ Output Belt Conveyor takes the dried sand into the storage area.

◆ Electric Control Panel is used to control all the above sand drying plant.