Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Home > Products > Crushing Machine >

As one of the typically rock crushing equipments in the world, Jaw crusher is mainly used for primary and secondary crushing Rock is dropped between two high manganese steel Jaw plates, one is fixed jaw plate, one is movable jaw plate Movable jaw plate moves up and down via eccentric shaft, and then crush the rock between the two jaw plates into smaller size

Technical Parameters

Overview of Jaw Crusher:

Jaw crusher is also named jaw breakers, rock crusher, or rock breaker. Jaw crusher is mainly used to primarily and secondarily crush many kinds of mining rocks, and the highest anti-pressure strength of crushed material is 320Mpa. Our design and production of jaw crusher are of high position both domestic and overseas.

Features of Jaw Crusher:

◆ Simple structure, reliable working condition, easy maintenance, low operating costs;

◆ High crushing ratio, even final partical size products ;

◆ Deep broken cavity, no dead zone, increased capacity ;

◆ Safe and reliable lubrication system, convenient replacement parts ;

◆ Stand-alone energy-saving 15% ~ 30% ;

◆ The discharging size of jaw crusher can be adjusted to meet the users' different requirements .

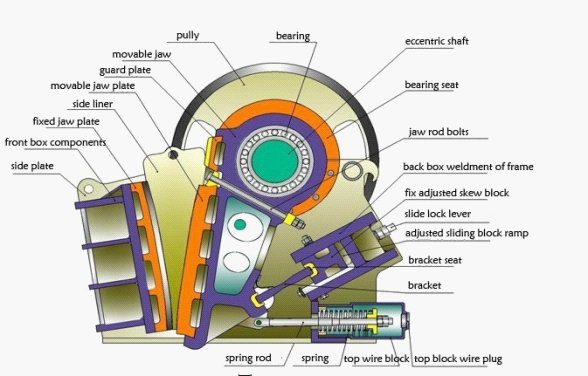

Structure of Jaw Crusher:

The structure of jaw crusher: main frame, eccentric shaft, a large belt pulley, fly wheel, swing jaw, side guard plate, toggle plate, Rear bracket, adjust gap screw, reset spring, and fixed jaw and swing jaw board etc., and the toggle plate also plays a role of protection.

Working Principle of Jaw Crusher:

◆ The motor drives the movable jaw plate to do periodic motion towards the fixed jaw plate by the eccentric shaft.

◆ The angle between toggle plate and movable jaw plate increases when movable jaw plate moves . So the movable jaw plate moves towards the fixed jaw plate.

◆ The material between the movable jaw plate and fixed jaw plate will be crushed in this process. The angle between toggle plate and movable jaw plate decreases when movable jaw plate moves down, the movable jaw plate moves leaves fixed jaw plate by pulling rod and spring, the final crushed material will be discharged from the outlet.

Technical Data of Jaw Crusher:

| Model | Inlet Size | Feeding Size | Discharge Size | Capacity | Power | Dimension | Weight |

| PE150X250 | 150x250mm | <125mm | 10-40mm | 1-3 t/h | 5.5kw | 896x745x935mm | 0.8 tons |

| PE250X400 | 250x400mm | <210mm | 20-60mm | 5-20 t/h | 15kw | 1150x1275x1240mm | 2.8 tons |

| PE400X600 | 400x600mm | <350mm | 40-100mm | 15-60 t/h | 30kw | 1700x1732x1653mm | 6.5 tons |

| PE500X750 | 500x750mm | <425mm | 50-100mm | 50-100 t/h | 55kw | 2034x1921x2000mm | 10.3 tons |

| PE600X900 | 600x900mm | <480mm | 65-160mm | 60-130 t/h | 22kw | 2290x2206x2370mm | 16.5 tons |

| PEX250X750 | 250x750mm | <210mm | 25-60mm | 10-40 t/h | 30kw | 1667x1545x1020mm | 5.0 tons |

| PEX250X1000 | 250x1000mm | <210mm | 25-60mm | 15-50 t/h | 37kw | 1550x1964x1380mm | 6.5 tons |

| PEX250X1200 | 250x1200mm | <210mm | 25-60mm | 20-60 t/h | 1560x2104x1415mm | 7.7 tons |

Notice: Any change of Jaw Crusher technical data shall not be advised additionally.

If you need more detail of our jaw crusher, please refer to:

◆ Video: http://www.youtube.com/watch?v=l0jx6KhNTuY

◆ Email: suncomachinery@hotmail.com

◆ Mobile/WhatsApp: +86 15838214261