Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Slag dryer also named slag drying machine Raw Slag dryer is ideal drying machine for the big moisture and high density materials such as blast furnace slag, limestone, clay, sand, etc The dried slag can be used into cement industry

Technical Parameters

Slag Dryer Application :

◆ Slag dryer is developed from rotary drum dryer. Raw Slag Dryer Machine is widely used in building materials, metallurgy, mineral processing, chemical, cement and other industries, mainly for the raw blast furnace slag, limestone, clay, sand, quartz sand, granulating slag and other wet materials with high intensity. After being dried by the slag drier, the dried slag can be used into the cement industry

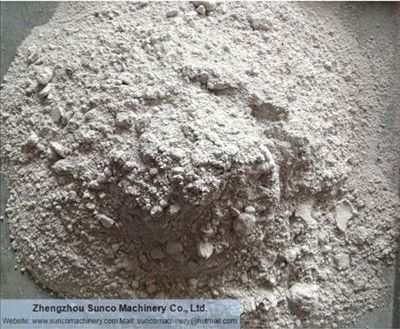

Wet Slag Dried Slag

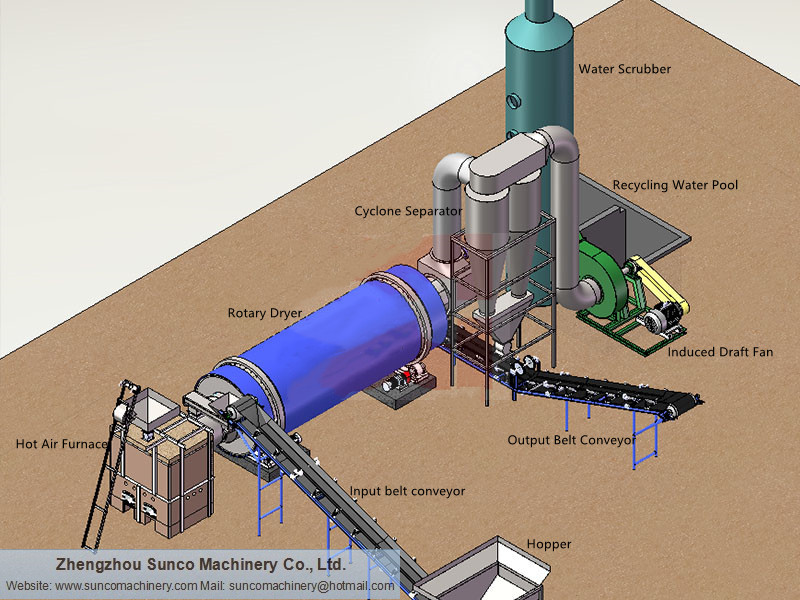

◆ Slag drying production line mainly consists of the rotating cylinder, high-speed breakup equipment, lifting plate, self-cleaning device, gear transimission device, hot air furnace, reducer machine, supporting device, sealing device, air duct system, dust cyclone separator,etc.

Slag Dryer Working Principle:

◆ Slag is relatively sticky. During the drying process, the wet slag will be transported into the feed hopper by belt conveyor. Feed hopper is directly connected to the drying cylinder, and the wet slag will goes into the drying drum by the feed hopper, begin to contact with the hot gas stream inside the drying drum, thereby starting the whole slag drying process.

◆ The entire slag drying process can be divided into three parts.

1.The wet raw slag contact with the hot air inside the drying drum, and the high temperature hot air heat the wet slag, and the moisture is evaporated;

2. There are many lifting boards which are welded on the inner wall of the rotating drying drum, and it not onel make the slag move forward, but also makes the wet slag up and down, during this process, the wet slag contact with the hot air sufficiently, and enhance the drying speed of slag;

3. There are special cleaning device inside the drying drum. During the drying process, it gets rid of the caking and adhesive material on the inner wall of the drying drum, thus prevent clogging.

Workflow of Rotary Slag Drying System:

>>> Hot air furnace and burner to burn the fuel, and creat the hot air for the slag drying process.

>>> Mechanical feeding hopper feeds wet raw slag onto input belt conveyor.

>>> Input Belt conveyor feed wet slag into rotary slag drying machine.

>>> In the rotary slag dryer, the wet slag is heated and dried, when the slag temperature is rising, the water is evaporated into vapor gradually.

>>> Under the action of induce draft fan, the hot flue gas goes into the rotary slag dryer, after the drying process, make the exhaust air and vapor out of the slag dryer drum in time.

>>> Cyclone dust separator is used to collect the fine dust mixed in the exhaust air.

>>> Water scrubber working together with recycling water pool to get rid of most of the rest fine dust from the exhaust air.

>>> Output belt conveyor takes the dried slag away from the slag drier, and send it to the product storage area.

>>> Electric control cabient is to control the whole rotary slag drying line.

Rotary Slag Dryer Advantages:

◆ Strong drying ability: Because the material is highly dispersed in the hot gas stream, the entire surface of the slag particles are the effective drying area.

◆ Short drying time.

◆ Simple and Reasonable structure, Small floor area needed, Easy construction and maintenance.

◆ Large capacity, high thermal efficiency. When dried the free water, the thermal efficiency of up to 75%.

◆ Achieve "zero thrust", greatly reducing the wear on the roller block, and the cylinder runs smoothly and reliably.

◆ The roller and rolling ring are always in linear contact, thereby greatly reducing the wear and power loss.

Specification of Rotary Slag Drying Machine:

Model | Input Capacity (T/H) | Input M.C.(%) | Output M.C.(%) | Dryer Motor (KW) | Heat Consumption (Kcal/hour) |

SC1012 | 5.0 |

10-20%

| 3%(adjustable) | 5.5 | 420,000 |

SC1212 | 8.0 | 11 | 650,000 | ||

SC1412 | 10.0 | 15 | 840,000 | ||

SC1512 | 15.0 | 15 | 1,300,000 | ||

SC1712 | 20.0 | 18.5 | 1,800,000 | ||

SC1912 | 30.0 | 22 | 2,800,000 |

Sunco Machinery can design and supply Rotary Slag Drying Machine, the needed information is as follows :

◆ Initial moisture content (%)of wet slag ?

◆ Final output moisture content (%) of dry slag needed ?

◆ Input Capacity (ton per hour ) needed ?

◆ Prefered fuel such as coal, waste wood, diesel, or natural gas, etc ?

◆ Other special requirements if have ?

If you are interested in our Slag Dryer Machine, please refer to:

◆ Email: suncomachinery@hotmail.com

◆ Mobile: +86 - 15838214261

◆ Video: