Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

Alfalfa Dryer by Sunco Machinery is airflow alfalfa drying unit for produce forage for animals Alfalfa Drying Machine is suitable for massive production of forage, and its fuel consumption is much less than the traditional rotary dryer

Technical Parameters

Alfalfa Dryer for forage Introduction:

◆ China is a major producer of alfalfa for forage, and the crop straw are everywhere. Some individual farmers even burn it as there is no place to storage. Local governments are always on high alert on every Autumn. Now more and more people realize that alfalfa is very good raw material for making animal feed, but the problem is that the price of the Alfalfa Dryer in the market is very much expensive, and the alfalfa operator does not have the ability to purchase the alfalfa dryer for drying forage, hay.

According to the aim of the customers, firstly the Alfalfa Drying machine can be used to pre-dry the wet forage to be moisture content about 60%-70%, and then use it produce silage; secondly the alfalfa dryng machine can be used to heat and dry the alfalfa / forage directly, and reduce the moisture content of the alfalfa / forage to be about 13% - 15% which is suitable for long term storage and making alfalfa / forage pellets as high quality animal feed.

◆ Sunco Machinery have devoted to the research and develop of alfalfa dryer for forage many years, and it is exciting that Sunco Machinery invent the double pulse airflow alfalfa drying unit early of the year 2000 which is suitable for massive promotion. What is more, its price is only about 70% of the tranditional rotary dryer.

Technical Error of the Tranditional Alfalfa Dryer for forage and hay:

◆ The Tranditional Alfalfa Dryer for forage is " Cylinder tube + Hot Airflow", and the cylinder tube are in series combination with the airflow. As there is no special moisture removal device on the cylinder tube, although the hot airflow heat the alfalfa when it goes through the cylinder tube, and much moisture is evaporated, but the moisture can not goes out of the cylinder tube independently. The moisture in steam type goes into the airflow drying system under the functions of high pressure draught fan.

◆ In other words, inside the cylinder tube, the mositure only become the steam, but its weight is still the same. So the moisture quantity in the drying system is still nearly as same as the moisture content in the alfalfa, and the cylinder tube nearly has no use here. Just like famous scientist professior Mr.Zhang said: "This is not technology, but it is just to sell steel to the customer with excessive profits. But most of the users who really know the secret of the alfalfa dryer. Most of the users only pay much attention to the big cylinder tube, but what is the actual use, they have no idea.

Key Points of Alfalfa Dryer:

◆ Direct Heated Hot Air Furnace:

The hot gas temperature at the outlet should be less than 700 ℃. As the hot air is contacted competely with the high moisture content alfalfa, inside the cylinder tube, the temperature of hot air is only about 200 ℃, and the actual contact temperature between hot air and alfalfa is only about 80 ℃, and only in this way, the alfalfa nutrition will not be destroyed.

◆ Function of knead machine:

The drying speed of stem and leaves is very different, V (Stem) : V(Leaves) = 3:1. For the fresh weight, M (Stem) : M (Leaves) = 3:1 . So we have to use the knead machine to deal with the alfalfa in advance so that the stem and leaves can be dried at a similar drying speed.

◆ Tightness of the whole Alfalfa drying system for Producing Forage and hay:

All the open mouth are sealed well. Otherwise under the high negative pressure of draught fan, the cold air will goes into the cylinder tube, and it will reduce the temperature of the hot air and increase the power of the draught fan. This is the key point for energy saving.

Workflow of Alfalfa Drying System:

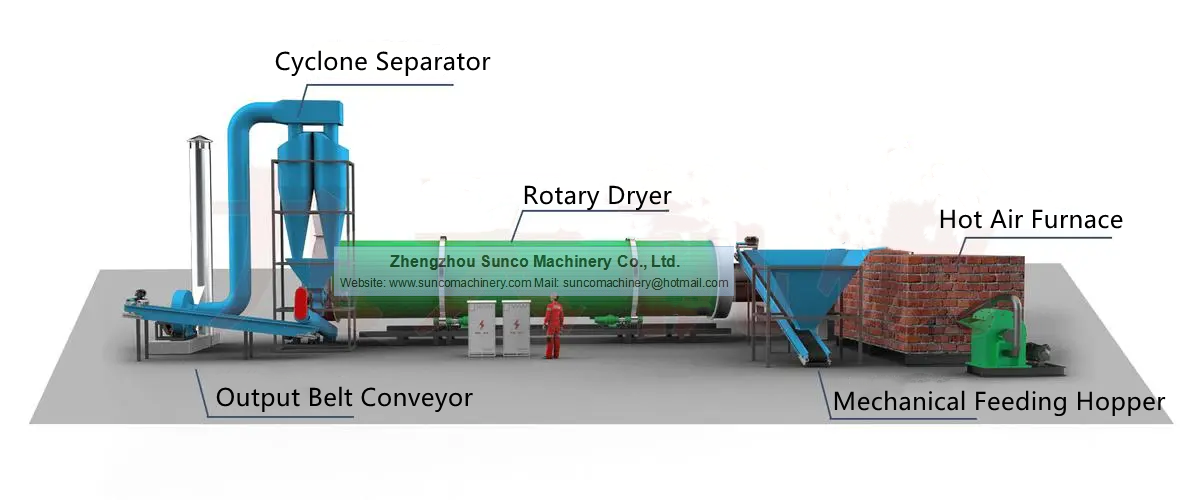

>>> Hot Air Furnace is to creat the high temperature air for the alfalfa drying process.

>>> Hay Chopper is to pulversize the alfalfa into small size less than 10cm in advance.

>>> Mechanical feeding hopper and input belt conveyor feeds the wet alfalfa into the rotary alfalfa dryer.

>>> Rotary Alfalfa Dryer Machine heat and dry the wet alfalfa, and get rid of the water quickly and continuously.

>>> Induced draft fan makes the hot air into the alfalfa drier cylinder, and sucks out the dried alfalfa and exhaust air out of the dryer machine.

>>> Cyclone separator is to collect the dry alfalfa.

>>> Output belt conveyor takes the dried alfalfa into the product packing area.

>>> Electric Control cabient is to control the whole alfalfa drying production line.

Service Commitment of Alfalfa Dryer for Producing Forage and Hay :

There are testing alfalfa dryer unit at our factory, and the customer can take alfalfa to have test to see the drying effect. Annual maintenance of equipment, 1 year warranty free of charge.

If you are interested in our Alfalfa Dryer Machine for drying forage and hay, please refer to:

◆ Email: suncomachinery@hotmail.com

◆ Mobile / WhatsApp: +86-15838214261

◆ Video:

https://www.youtube.com/watch?v=KKBvWBGgLEY

https://www.youtube.com/watch?v=32-84CV636w&feature=youtu.be

http://www.youtube.com/watch?v=jjfxwqmdAiQ&feature=youtu.be