Menu

Rotary Dryer, Drying Machine, Raymond Mill, Stone Crusher

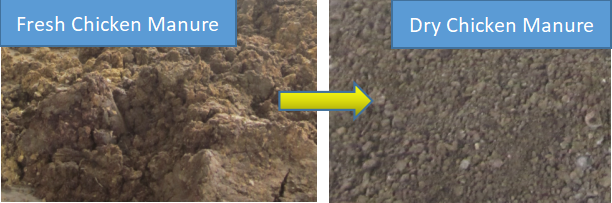

Chicken Manure Dryer Machine can quickly dry fresh chicken manure with moisture content of 70% to 80% down to a moisture content of only 13% The dried chicken manure can be used as Organic Fertilizer, Animal Feed with good economic benefit

Technical Parameters

Chicken Manure Dryer Machine can Efficiently Process and Dry High Humidity

Chicken Manure and Creat More Benefits

In modern poultry farming industry, waste treatment and resource recycling have always been the key issues. Chicken manure is a nutrient-rich organic fertilizer resource. But without proper processing, not only it will cause serious flies problems and strong odor to pollute the environment, but also it can not be used as organic fertilizer directly which will burn plants' roots. Its utilization value will be greatly improved if it can be properly processed. Chicken manure dryer is the key equipment to solve this problem. Similar to the working principle of organic fertilizer dryers such as cow dung dryer, this equipment not only can efficiently dry the chicken manure but also has multiple functions such as dust removal and deodorization to ensure that the treatment process is environmentally friendly and efficient.

No need additional dewatering device, Chicken manure dryer machine can quickly dry fresh chicken manure with moisture content 70% to 80% down to moisture content only 13% within around 25-30 minutes. This high-efficiency moisture removal capability ensures that chicken manure retains its optimal nutrient content during the conversion process, making it easier for further processing and utilization. Chicken manure drying system operates in a fully enclosed state, effectively reducing environmental pollution while being energy-saving and environmentally friendly. The dried chicken manure can be used to produce high-quality organic fertilizer and feed additives, creating more benefits for the poultry farm owners.

| Model | Input Capacity (T/H) | Input M.C.(%) | Output M.C.(%) | Dryer Motor (KW) | Heat Consumption (Kcal/hour) |

| SCM1112 | 1.0 | 40-50% or 70-75% | 13-20%(adjustable) | 5.5 | 260,000 or 390,000 |

| SCM1312 | 1.5 | 7.5 | 440,000 or 680,000 | ||

| SCM1316 | 2.0 | 11 | 600,000 or 910,000 | ||

| SCM1515 | 2.5 | 15 | 680,000 or 1,150,000 | ||

| SCM1518 | 3.0 | 15 | 890,000 or 1,460,000 | ||

| SCM1718 | 4.0 | 18.5 | 1,150,000 or 1,820,000 | ||

| SCM1918 | 5.0 | 22 | 1,450,000 or 2,270,000 |

Chicken Manure Dryer Specification

Chicken Manure Dryer is the Key Equipment for High-quality Organic Fertilizer Poduction

Chicken manure dryer machine is the key equipment for making chicken manure organic fertilizer. For making Chicken manure organic fertilizer, usually there are two processing methods:

One is directly to use Chicken Manure Dryer to dry the fresh chicken manure and reduce its moisture content to be around 13%, and the dried manure can be directly used as organic fertilizer.

The other is to use fresh chicken manure as the main raw material, meantime being mixed with rice husk or sawdust, fermentation bacterials, and it is made through raw material pretreatment, mixing, fermentation, granulation, drying, and cooling.

The organic fertilizer produced is rich in nutrients such as nitrogen, phosphorus, and potassium, as well as a high proportion of crude protein and organic matter, which can significantly increase soil fertility and crop yields. Tests by experts from the Academy of Agricultural Sciences show that chicken manure organic fertilizer is a high-quality fertilizer choice in agricultural production.

Related Equipments of Chicken Manure Organic Fertilizer Production Line

Chicken Manure Dryer Rotary Cooling Drum

Rotary Drum Sieve Granulator

◆ Raw material pretreatment: To mix wet chicken manure with auxiliary materials such as rice husk,fermentation bacterials under certain ratio.

◆ Fermentation Device: Use fermentation tanks or compost turners for aerobic fermentation of raw materials.

◆ Chicken Manure Dryer: After fermentation, the moisture content is still around 40%-50%, then use Chicken Manure Dryer to dry and reduce its mosture conent to be around 20%.

◆ Granulation equipment: Such as pellet mill.

◆ Cooling Equipment: Cool the granulated products through rotary cooling drum.

◆ Screening and packaging equipment: Screen out the qualified chicken manure pellets by screening machines and package them by automatic packaging machines.

Chicken Manure Drying System For Turning Chicken Manure into Treasure

Chicken manure drying system is not only suitable for the production of organic fertilizer, but also can be used to make animal feed additives.

Dried chicken manure can be directly added to fish feed, pig feed and fruit tree fertilizer, becoming an important nutritional supplement.

In the fields of large-scale composting fermentation production, chicken manure drying system is necessary to dry the wet chicken manure. By converting fresh chicken manure into high-value-added products, the chicken manure dryer realizes the resource utilization of waste, reduces environmental pollution, and promotes the sustainable development of poultry farming.

Organic Fertilizer

Chicken Manure Organic Fertilizer Pellets

For large-scale organic fertilizer production line, using a large chicken manure dryer machine is more efficient. The manure drying system can process chicken manure quickly and reduce the moisture content to the standard and guaranteeing the quality of the final product.

Animal Feed Additives:

To be used as animal feed additives, thoroughly drying and sterilization are essential to ensure product hygiene and quality. Chicken manure drying system can provide stable high temperature drying condition, ensuring safety.

Fermentation & Composting:

Composting & fermentation

For large-scale fermentation & composting, chicken manure drying system can accelerate processing and shorten the time needed, and ensure the even drying of chicken manure, which is beneficial for the subsequent production of organic fertlizer pellets.

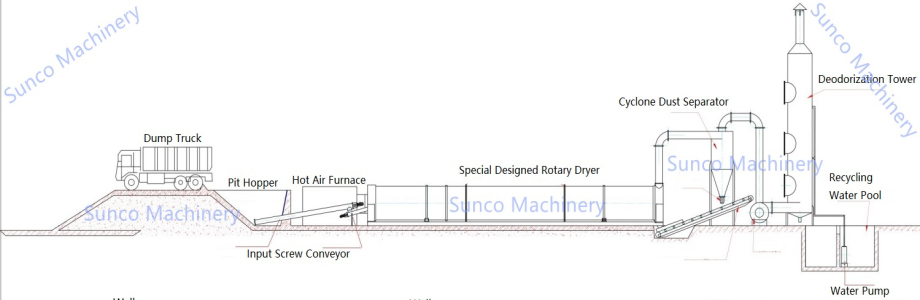

Chicken Manure Drying System Consists of : Burner & Hot Air Furnace, Wet Manure Feeding Machine, Chicken Manure Dryer, Dried Manure Discharging Machine, Induced Fan & Cyclone Separator, Dust Removal Machine, Deodorization Tower.

Select Sunco Chicken Manure Dryers for Efficient and Eco-Friendly

Poultry Farming

In the modernization of Poultry Farming Industries, chicken manure dryer machines has become indispensable equipment. It does not only efficiently process chicken manure, converting waste into valuable organic fertilizer and feed additives, but also significantly reduce environmental pollution, promoting sustainable development. Among the many chicken manure dryer products available in the market, Sunco stands out with our advanced technology, superior quality, reasonable price and comprehensive after-sales service, earning the trust and praise of numerous customers.

Chicken Manure Dryer & Organic Fertlizer Pellet Plant for Thailand CP Capacity 5 t/h Chicken Manure Dryer for Fiji Clients is ready

Sunco chicken manure dryer adopts the latest drying technology, offering high heating efficiency, less fuel consumption, and environmental friendly. With fully enclosed operation, these dryers prevent secondary pollution, ensuring a clean and sanitary production process. Sunco provides a variety of capacities and sizes dryers to meet the needs of different scales of poultry farms. No matter you run a large-scale farm requiring substantial manure processing or a smaller operation needing a cost-effective solution, Sunco all can design and supply the suitable dryer for you.

Choosing Sunco chicken manure dryer means opting for a high-quality, high-efficient, and environmentally friendly chicken manure processing solution. Sunco are committed to providing the best manure dryers and professional services, helping you achieve both green development and economic benefits.

Advantages of Chicken Manure Dryer :

◆ Reasonable Inner structure helps to increase the heat contact area between hot air and wet chicken manure, with high heat exchanging efficiency.

◆ Triple Pass Drying, and chicken manure passes through the dryer drum 3 times, ensure longer drying time.

◆ New type Deodorization tower with patent, environment friendly;

◆ Compact Structure with better body balance, horizontal installation.

◆ Quick & continuous drying process, within about 25 minutes can get the dry manure.

Fuel Options for Chicken Manure Dryer : Waste Wood, Coal , Biomass Pellet, Diesel, Natural Gas, LPG, etc.

Information needed to customize Chicken Manure Drying System :

◆ Initial moisture content (%) of wet chicken manure which is ready to be dried ?

◆ Output moisture content (%) of dry chicken manure needed ?

◆ Input Capacity (ton per hour) needed ?

◆ Prefered fuel such as waste wood, coal, diesel, or natural gas, etc ?

◆ Other special requirements if have ?

For detailed solution of Chicken Manure Dryer, please feel free to contact us :

◆ Email: suncomachinery@hotmail.com

◆ Mobile/WhatsApp: +86-15838214261

◆ Video Links: